Dongguan Dingyi Printing Co., Ltd

From design to product completion, Dingyi provides customers with one-stop services.

Dongguan Dingyi Printing Co., Ltd. is one of the water transfer printing products and trading companies, with more than 20 years of technical experience in customizing and designing various water label stickers for brands such as golf, bicycles, and helmets around the world. Our company mainly deals in water transfer printing products, heat transfer printing, pressure-sensitive printing, anti cursor and hot silver printing, and other special products. With its own R&D team and advanced production equipment, Dingyi always brings excellent quality and new designs to customers. From design to product completion, Dingyi provides customers with one-stop services. Dingyi continuously develops and innovates in response to customer needs, and has established companies in Taiwan, and the Philippines in China.

Customer first, technological excellence, excellent quality, unity and cooperation, and seeking truth and pragmatism are the eternal corporate spirit of our company.

I am proud to have dedicated my most precious time tothe industry ofenvironmentalprinting,and lamhonored to contribute to the cause of environmentalprotection together with my team. In the years to comewe insist on meeting the needs of our customers with thebestproducts and the best services to create a betterand brilliant tomorrow.

Colour Huang

Chairman

Corporate Culture

Corporate Philosophy

Based on service,persisting in quality forliving,technology for development,innovation for market,and integrity for respect.

Service Tenet

Quality first,customer first, efficient service and common development.

Company Commitment

Integrity,realism,innovation,win-win.

Production Process

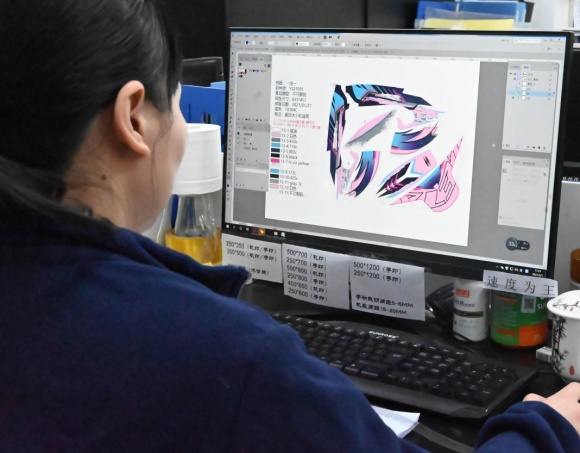

We can design and planyour water transfer decalsfor a whole year according to your ideas

1. Provide samples or drawings as well as customer requirements.

2.Typesetting separations and film output are designed and printed by computer according to customer requirements.

3. Depending on customer color preferences, color swatches are created and loaded onto the color card for printing.

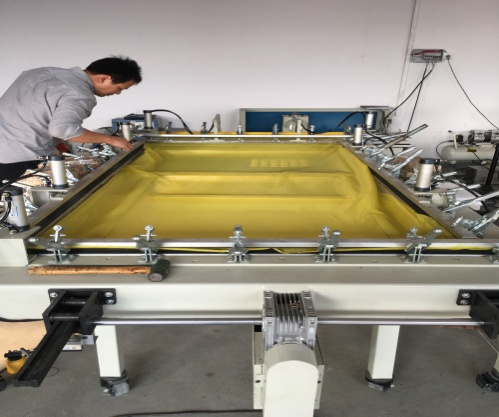

4. According to printing requirements a printing plate is created.

5. After proofing rooms print is complete a sample product is detected.

6. Then the development department is accordance with the customer's sample reviews re-proofs the sample.

7. Production of large quantities according to standard process cards

8. Inspection and sampling in production.

9. Product inspection, sorting and shipping.

Development History

Qualification Certificate

ISO,SGS,RoHS,MSDS